The Silent Partner Demanding Attention: Why Regular Air Filter Changes Are Non-Negotiable for Peak Performance

For over two decades, I've navigated the intricate world of Air Filtration – from the dust-choked floors of heavy manufacturing to the pristine environments of microelectronics, and the vast networks of commercial HVAC systems keeping our buildings breathing. One truth resonates louder than any sales pitch, any technical specification: the most sophisticated air filter is only as good as its maintenance schedule. Neglecting regular replacement isn't just an oversight; it's a costly gamble with performance, efficiency, compliance, and ultimately, your bottom line and environmental responsibility. At KWS, we don't just sell filters; we sell optimized air quality solutions, and central to that solution is the disciplined practice of timely filter changes. Let's cut through the complacency.

Beyond Clogged Filters: The Cascading Impact of Neglect

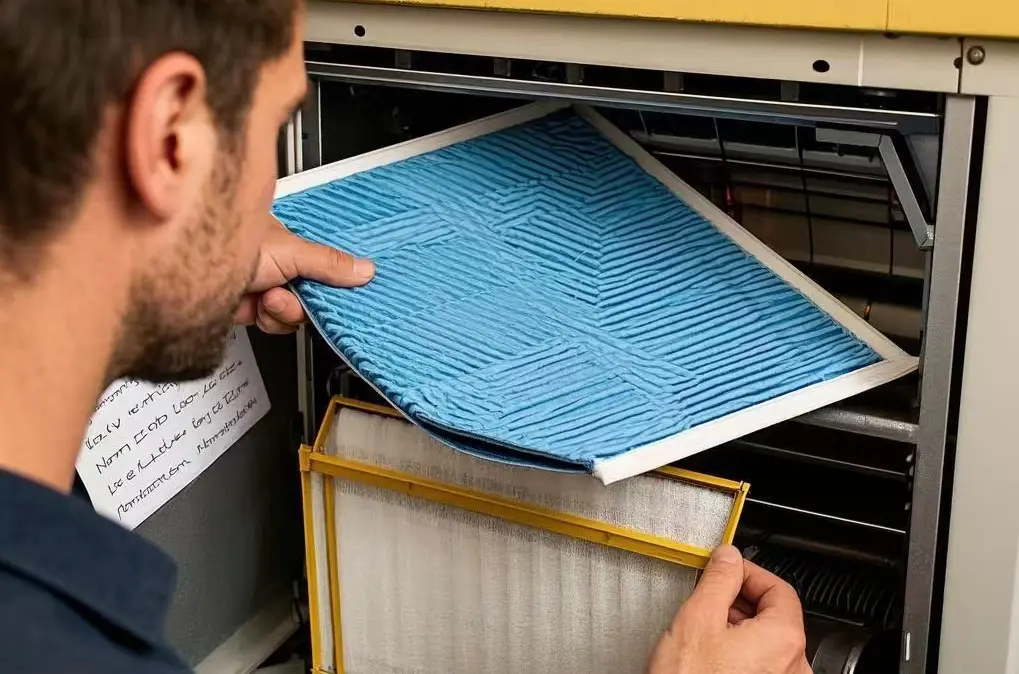

It’s easy to fall into the "out of sight, out of mind" trap. Filters work silently, often tucked away in mechanical rooms or equipment housings. But when that scheduled change is deferred, the consequences are far from silent:

1.The Efficiency Erosion & Energy Drain: This is the most immediate and quantifiable hit. As filters load with particulate matter, the resistance to airflow – the pressure drop – increases dramatically. Your fans and blowers must work exponentially harder to push air through the clogged media. The U.S. Department of Energy estimates that a heavily loaded Filter Can increase HVAC energy consumption by 15% or more. In an industrial setting running large air handlers 24/7, this translates to staggering, unnecessary operational costs. KWS filters are engineered for optimal dust holding capacity and controlled pressure drop rise, but even our high-performance media has its designed limit. Pushing beyond it is simply burning money.

2.Performance Compromise & System Strain: Your filtration system has a specific job: protect equipment, processes, or indoor air quality (IAQ). A saturated filter cannot perform this task effectively.

Industrial: In critical applications like paint booths, pharmaceutical production, or food processing, compromised filtration means contaminants reach sensitive products or machinery, leading to rejects, rework, equipment wear (increased maintenance costs), and potential safety hazards (e.g., combustible dust accumulation). Protection fails at the final hurdle.

HVAC/New Air Systems: For buildings, overloaded filters become a source of contamination themselves. They can harbor mold, bacteria, and allergens, which are then redistributed into the occupied space. IAQ plummets, potentially leading to occupant discomfort, health complaints ("Sick Building Syndrome"), and reduced productivity. Moreover, the strain on the HVAC system – coils icing up, reduced heat exchange efficiency, potential fan motor burnout – leads to premature failures and costly emergency repairs. Your fresh air system becomes a liability.

Environmental Control: In scrubbers or emission control units, failure to maintain optimal filtration can lead to exceeding permitted emission levels, resulting in regulatory fines and reputational damage. Capture efficiency drops when filters are overwhelmed.

3.The Shortened Lifespan Domino Effect: The excessive strain caused by high pressure drop doesn't just affect energy bills; it accelerates the wear and tear on your entire air handling system. Bearings in fans and motors overheat, belts slip and wear faster, and the system operates constantly under stress. This significantly shortens the lifespan of expensive capital equipment, forcing premature replacements that could have been avoided with disciplined filter management. It's a classic case of neglecting a relatively minor cost (filter replacement) leading to massive capital expenditure down the line.

4.Compliance & Liability Risks: Many industries operate under strict air quality regulations, both for worker safety (OSHA, COSHH) and environmental emissions (EPA, local regulations). Regular filter changes, documented as part of a preventative maintenance program, are often a fundamental compliance requirement. Failure to demonstrate this due diligence can lead to significant fines, operational shutdowns, and increased liability in the event of health or safety incidents linked to poor air quality. KWS filters are designed and tested to meet stringent standards (ISO 16890, EN779, ASHRAE 52.2, specific MERV/HEPA ratings), but their certified performance is only valid when maintained correctly and replaced on schedule.

KWS: Your Partner in Predictable Performance and Cost Control

At KWS, we understand that specifying the right filter is only half the battle. Our commitment extends to ensuring you maximize the value and performance of your investment through optimal maintenance practices. Here’s how partnering with KWS supports your commitment to regular replacement:

Precision Engineering for Predictable Life: Our filters aren't just about initial efficiency; they are engineered for consistent performance and predictable pressure drop rise curves. This allows for accurate scheduling of replacements based on actual operating conditions and differential pressure monitoring, not just arbitrary time intervals.

Durability & Value: KWS media and construction are built to handle demanding industrial and commercial environments, maximizing dust holding capacity within the optimal pressure drop range. This means longer effective service life where it counts, without pushing the system into inefficient operation.

Expert Guidance & Support: Leverage our decades of application expertise. We help you establish the *correct* replacement schedule based on your specific environment, contaminant load, system design, and criticality. We provide clear documentation and support your maintenance teams.

Inventory Management Solutions: Avoid costly downtime due to lack of spares. KWS offers tailored programs to ensure you have the right filters, in the right quantity, available precisely when needed.

The Bottom Line: An Investment, Not an Expense

Viewing air filter replacements solely as a cost is a fundamental mistake. It is a strategic investment with a clear, measurable ROI:

Reduced Energy Consumption: Slash your utility bills significantly. Protected Capital Equipment: Extend the lifespan of expensive fans, coils, and motors.

Uncompromised Product Quality & Process Integrity: Minimize rejects, rework, and contamination risks.

Enhanced IAQ & Occupant Well-being: Foster a healthier, more productive environment, reducing absenteeism.

Regulatory Compliance & Risk Mitigation: Avoid fines, shutdowns, and liability.

Environmental Stewardship: Lower energy consumption directly reduces your carbon footprint.

Don't let a relatively minor maintenance task become the weak link that compromises your entire operation, inflates your operating costs, or jeopardizes compliance. Proactive, scheduled filter replacement is the cornerstone of efficient, reliable, and responsible air quality management.

Partner with KWS.

Let us provide not just the superior filters your systems demand, but the expertise and support to ensure they deliver their full potential, change after timely change. Contact your KWS representative today to audit your current filtration strategy and build a proactive maintenance plan that turns your air filtration system from a potential liability into a demonstrable asset. Your bottom line, your equipment, and the air you depend on will thank you.