Revolutionizing Production – A New Era of Efficiency in Manufacturing

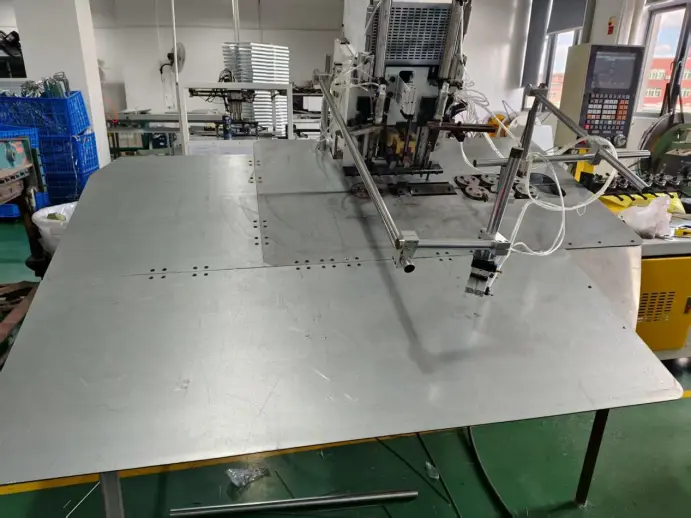

Hey everyone! Big news from our production side—we’ve just rolled out two cutting-edge machines: a wire bending machine and a glue filling machine. This is a real game-changer for us and totally ups our manufacturing game. The introduction of these machines marks a pivotal moment in our production capabilities, as they address key challenges like speed, quality, and environmental responsibility, positioning us for long-term growth.

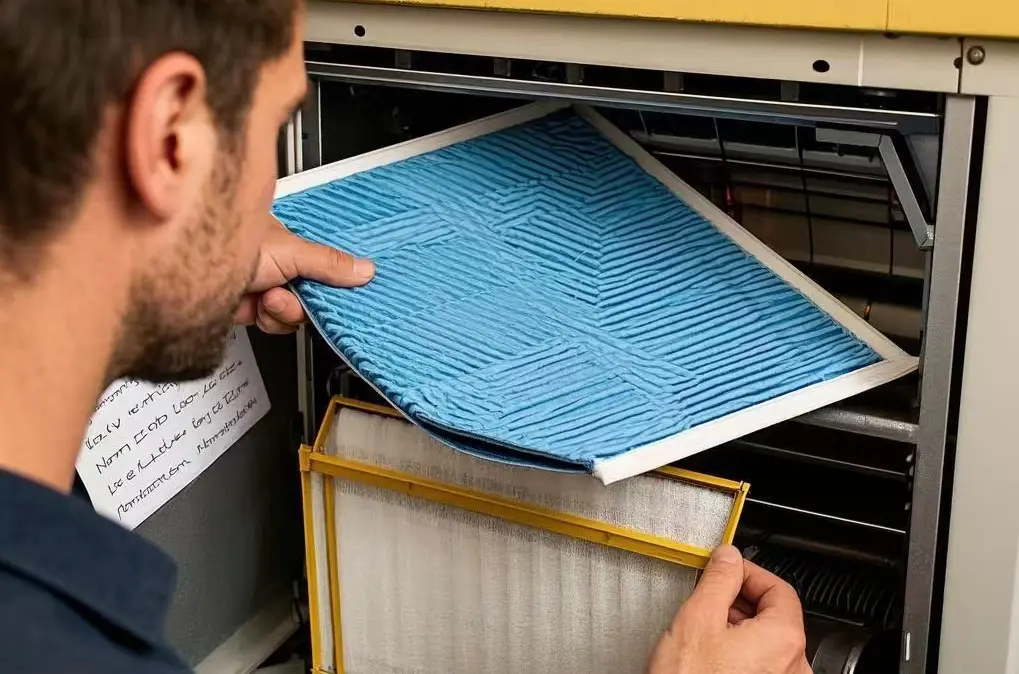

First, let’s talk about the wire bending machine—a state-of-the-art piece of equipment designed specifically for producing our nylon Mesh Filters and related components. This machine leverages the latest automation technology, significantly streamlining the wire bending process. Previously, manual bending required considerable time and effort, often resulting in inconsistent results or human errors. With the new machine, we’ve witnessed a remarkable decrease in processing time; what used to take hours can now be completed in minutes. More importantly, automation ensures that every product meets the same exacting quality standards, eliminating the variability that comes with manual labor. This consistency is crucial because our customers rely on us to deliver top-notch products, and even small inconsistencies could compromise performance. Additionally, the increased speed directly responds to the growing demand from our clients, allowing us to fulfill orders faster without sacrificing quality.

On the other hand, the glue filling machine is making a substantial impact on our assembly line operations. Designed to seamlessly integrate with our existing production setup, this machine optimizes the adhesive application process. One of its standout features is its precision—it applies adhesive precisely where needed, every single time. In the past, manual glue application was prone to errors like over-applying or under-applying, which could weaken the final product or cause assembly issues. Now, with the new machine, we achieve perfect adhesion consistently, ensuring the strength and reliability of our products. Moreover, by automating this task, we’ve reduced reliance on manual labor, making our production line more reliable and efficient. This reduction in manual work also allows our team to focus on other critical tasks, further boosting overall productivity and enabling us to increase our output capacity. This upgrade clearly showcases our commitment to investing in technology that drives growth and keeps up with the rapidly evolving market demands.

Beyond enhancing production efficiency, these upgrades play a vital role in promoting environmental responsibility and workplace safety. Alongside the high-efficiency filters and primary filters we manufacture, these new machines complement our existing Filtration Systems, which excel at capturing airborne contaminants. With the improved production processes, we ensure that our filters are manufactured with even greater precision, thereby improving air quality in our workshops. Better air quality isn’t just beneficial for the environment; it’s essential for the health and well-being of our employees. By reducing dust, particles, and other pollutants in the air, we create a safer, healthier workspace. This aligns perfectly with our commitment to sustainable manufacturing practices—we’re not just focused on increasing efficiency; we’re dedicated to protecting the environment and supporting the health of our workforce. Every upgrade we implement reflects our goal of balancing technological advancement with ecological responsibility, ensuring we contribute positively to both our business success and the broader community.

All in all, these innovative machines represent more than just improvements to our production line—they embody our vision for the future of manufacturing. By combining cutting-edge technology with eco-conscious practices, we’re setting a new standard for how companies can thrive while caring for the environment and their workforce. As we continue to evolve and adapt, these advancements will help us build a brighter, more efficient future—one that prioritizes quality, sustainability, and innovation. We’re proud to embrace these changes, knowing they’ll benefit our customers, our employees, and the planet alike. These innovations reflect our commitment to revolutionizing production, creating a new era of efficiency that’s both productive and responsible.