Leave Your Message

Determining the right price for a Plate Primary Efficiency Medium Filter can be challenging. Various factors impact the final cost, leading to variations in market prices. Understanding these elements is key for consumers and businesses alike.

The quality and efficiency of the filter play a significant role in pricing. Higher efficiency often means a higher price tag. Yet, this isn’t always straightforward. Some brands offer similar efficiencies at different prices. This creates confusion in choosing the right filter.

Consider the size, material, and brand reputation as well. These details influence the Plate Primary Efficiency Medium Filter Price. Ignoring these aspects can result in a poor investment choice. Reflecting on your specific needs will guide you in making an informed decision. Ultimately, it's about finding the right balance between cost and quality.

Understanding Plate Primary Efficiency Medium Filters is crucial for many industrial applications. These filters are designed to operate efficiently under specific conditions. Their primary function is to enhance the quality of fluid by eliminating contaminants. This process often results in increased system longevity and reliability.

Recent industry reports indicate that optimal filter performance can significantly reduce operational costs. For instance, a well-maintained medium filter can improve efficiency by up to 30%. This means less energy consumption and lower maintenance expenses. However, not all operations achieve this efficiency. Inadequate maintenance practices lead to poor filtration and increased fouling. It is essential to regularly assess filter conditions.

Moreover, it is vital to consider environmental factors that impact efficiency. Temperature fluctuations and fluid viscosity can alter filtration capabilities. Studies show that filters operating outside their designed parameters can underperform, sometimes by as much as 50%. Organisations need to evaluate their systems continuously. This will ensure they are using filters that meet their specific needs effectively. Implementing a robust monitoring system can help to determine when filters require replacement.

When looking at medium filter prices, various factors come into play. The quality of materials affects the cost significantly. High-grade materials often lead to higher prices, but their durability can justify the expense. Filters with more advanced technology tend to be pricier as well. They provide better efficiency and longer lifespan, which can save money in the long run.

Installation and maintenance costs are also important. A complex filter system may require professional installation. This adds to the overall price. Regular maintenance can be costly too. Users should consider these factors before making a purchase.

Tips: Always compare different options. Gather quotes from multiple suppliers. Being informed helps avoid overspending. Also, assess your specific needs. Sometimes, a budget filter might suffice. Don't overlook the potential trade-offs between price and efficiency. Making careful choices can lead to better results over time.

When evaluating medium filters, it's crucial to understand the differences between brands. Research indicates that the efficiency of filters can vary widely. Key performance metrics include filtration rate and debris capture. According to recent reports, some premium brands achieve up to 95% efficiency. However, not all high-priced options offer superior results.

In contrast, less expensive brands can deliver a satisfactory performance. Data reveals that some of these budget options still meet industry standards. They may filter out 80% of contaminants. The trade-off here could be lifespan versus performance. Many buyers overlook the longevity aspect. While budget filters may save money upfront, they often require more frequent replacements.

Comparative analysis suggests that not all filters are created equal. Some brands are designed for specific applications. It's critical to match the filter type to the intended use. Consumers often face confusion with numerous choices available. It's a common pitfall to assume that a higher price guarantees better efficiency. Awareness of these factors can lead to more informed decisions when selecting a filter.

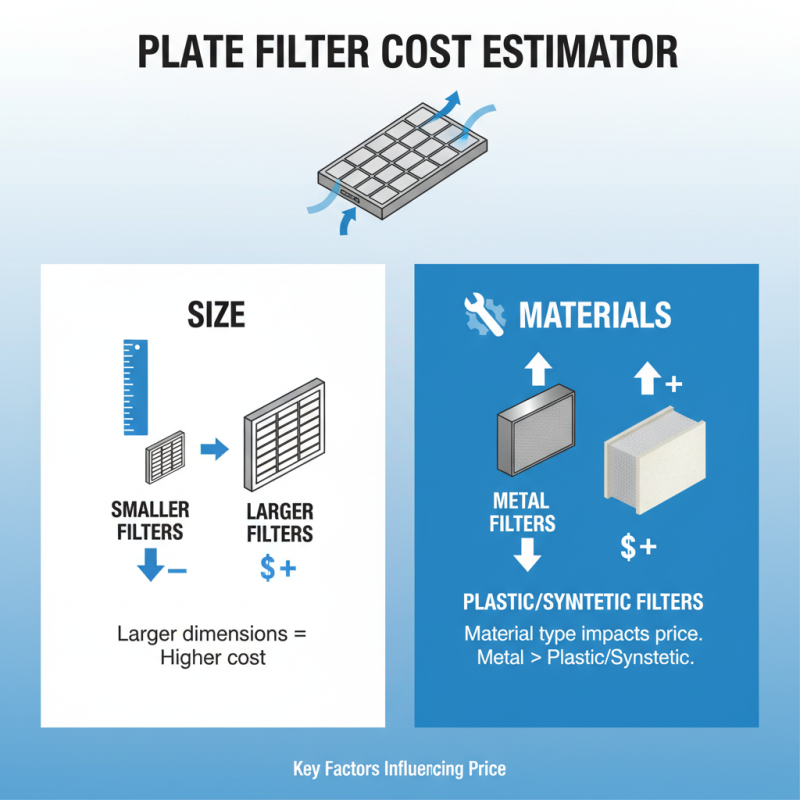

Estimating the cost of plate primary efficiency medium filters can be quite challenging. Various factors play a role in determining the final price. For instance, filter size and construction materials greatly influence costs. Larger filters tend to be more expensive. The material used also adds to the complexity of the pricing. Metal filters may cost more than those made from plastic.

Additionally, the production techniques and technology utilized matter. Some manufacturers may use advanced technologies that enhance filter performance but can increase costs. It's essential to balance your budget and quality. Sometimes, a lower-priced filter might not deliver the desired efficiency. This can lead to higher operational expenses in the long run.

Do not overlook installation and maintenance costs. These factors can add up quickly. When estimating total expenses, consider the lifespan of the filter too. A more expensive filter might last longer, ultimately saving you money. It's vital to review and reflect upon the overall value you seek.

When budgeting for medium filters, it’s essential to understand the range of prices. Reports indicate that the cost can vary significantly. Industry surveys show that prices can range from $30 to $150 per filter. Factors influencing this include material quality and filter efficiency ratings.

Consider operational needs carefully. Some applications may require higher filtration efficiency, which often costs more. However, investing in high-quality filters can lead to longer service life and fewer replacements. According to industry data, lower-priced filters may need to be replaced more frequently, negating potential savings.

It's worth reflecting on your filter choice. Sometimes, the cheaper option might not deliver the necessary performance. A balance between cost and efficiency should guide your purchasing decisions. Remember to account for long-term costs, not just the upfront price.