Leave Your Message

In the rapidly evolving world of air and water filtration, choosing the right products is crucial for maximizing efficiency and ensuring safety. As the demand for clean air and water rises, the significance of wholesale activated carbon filter sheets has come to the forefront. Expert in environmental engineering, Dr. Jane Thompson, states, "Selecting the right activated carbon filter sheet can dramatically enhance the performance of filtration systems, reducing contaminants at a molecular level." Her insight emphasizes the importance of making informed decisions when sourcing these essential components.

When delving into the realm of wholesale activated carbon filter sheets, it is essential to consider various factors including material quality, porosity, and intended application. Buyers must carefully assess their specific needs, as not all activated carbon sheets are created equal. By understanding the nuances of these products, you can select a filter sheet that not only meets your filtration requirements but also aligns with your budget and sustainability goals.

Ultimately, navigating the market for wholesale activated carbon filter sheets requires a blend of knowledge and strategic planning. By leveraging expert insights and thorough research, you can ensure that your selection contributes effectively to improved air and water quality, making it a worthwhile investment for both immediate and long-term environmental health.

Activated carbon filter sheets are essential components in various applications including air and water purification, odor control, and industrial processes. Comprised of highly porous carbon material, these sheets effectively adsorb impurities, volatile organic compounds (VOCs), and other contaminants. According to a report by Research and Markets, the global activated carbon market is projected to reach $5.5 billion by 2027, highlighting the growing demand for such filtration solutions.

When selecting the right activated carbon filter sheet, it is crucial to consider factors such as thickness, pore size, and the specific type of contaminants you aim to filter. For instance, thicker sheets typically offer better filtration but may reduce airflow, making them less suitable for applications requiring high air volume. Understanding the specific needs of your application, whether for residential use or industrial settings, will help you choose the most effective solution.

**Tips:** Always check the manufacturer’s specifications for adsorption capacity and filter lifespan. It’s also beneficial to review third-party test results to ensure the filter's effectiveness against the contaminants you are targeting. Additionally, consider the operational environment, as factors like humidity and temperature can significantly affect filter performance.

When selecting wholesale activated carbon filter sheets, several key factors must be considered to ensure that you meet your specific needs. Firstly, the type of activated carbon used is crucial. Granular activated carbon (GAC) and powdered activated carbon (PAC) perform differently and are suitable for distinct applications. According to a report from the Environmental Protection Agency (EPA), GAC is generally more effective for removing larger particles and organic compounds, while PAC is better for treating smaller contaminants. Understanding these differences will help you determine which type is best suited for your filtration requirements.

Additionally, the effectiveness of activated carbon filter sheets often depends on their surface area and pore structure. A study published by the Journal of Environmental Science and Technology indicates that higher surface area and optimal pore distribution significantly enhance adsorption efficiency, leading to better contaminant removal rates. When assessing wholesale offers, it is essential to obtain specifications that detail the surface area in square meters per gram and the distribution of pore sizes. This technical data will aid in comparing different suppliers and ensuring that the chosen product effectively meets your filtration goals. Prioritizing these key factors not only optimizes performance but also contributes to cost-effectiveness in your overall filtering system.

| Dimension | Material Type | Thickness (mm) | Adsorption Capacity (mg/g) | Application | Price per Unit ($) |

|---|---|---|---|---|---|

| 20 x 20 cm | Coconut Shell | 5 | 800 | Air Purification | 2.50 |

| 30 x 30 cm | Wood-based | 4 | 600 | Water Treatment | 3.00 |

| 50 x 50 cm | Coal-based | 6 | 1200 | Industrial Filtration | 4.00 |

| 25 x 25 cm | Rice Husk | 3 | 550 | Gas Treatment | 2.00 |

When selecting the best wholesale activated carbon filter sheet, evaluating quality through certifications and specifications is crucial. Key certifications to consider include ANSI/NSF standards, which ensure that the materials used meet safety and efficacy requirements for various applications, including water treatment and air filtration. According to the Global Activated Carbon Market report, the increasing regulatory standards are driving demand for certified products, indicating that consumers should prioritize filters that are compliant with such industry benchmarks.

In addition to certifications, examining the specifications of activated carbon sheets can provide insight into their performance capabilities. Parameters such as iodine number, which measures the surface area and adsorption capacity, and ash content, which indicates the purity of the carbon, play a vital role in determining filter efficiency. For instance, a higher iodine number typically correlates with better absorptive qualities, making it an essential factor for industries requiring optimal filtration solutions. Referring to the Activated Carbon Manufacturers Association (ACMA), products with a specific surface area greater than 800 m²/g are often recommended for high-demand applications, showcasing the significance of technical specifications in ensuring a reliable choice for your filtration needs.

This chart illustrates key quality metrics for activated carbon filter sheets, including granular size, adsorption capacity, iodine number, ash content, and moisture content. Each metric is essential for assessing overall effectiveness and suitability for specific applications.

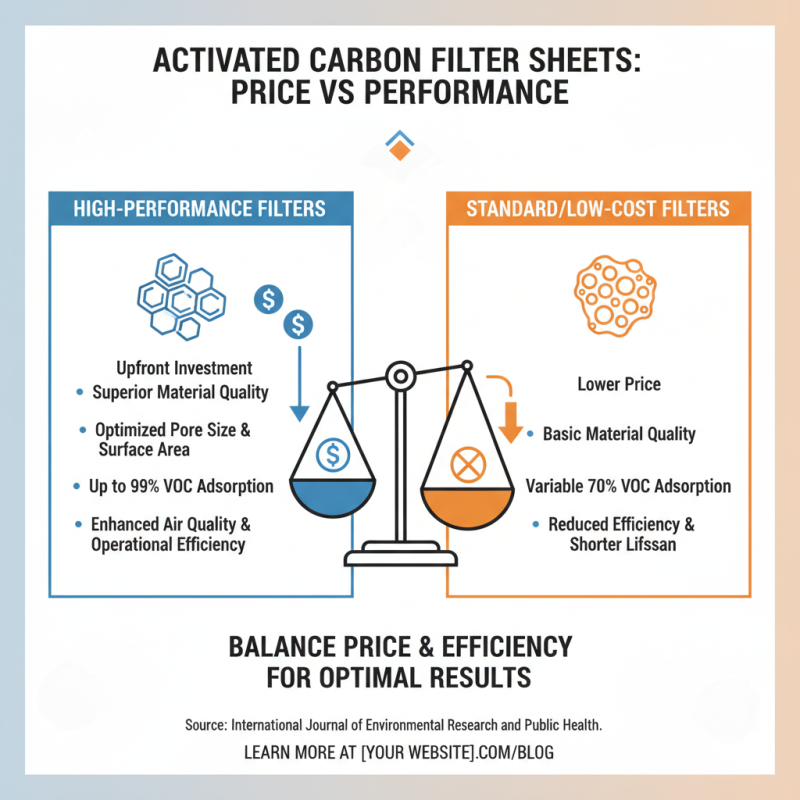

When considering the best wholesale activated carbon filter sheets, it’s crucial to evaluate the delicate balance between price and performance. Recent industry studies indicate that the efficiency of activated carbon filters primarily depends on their surface area, pore size, and material quality. A comprehensive report from the International Journal of Environmental Research and Public Health illustrates that high-performance filters can adsorb up to 99% of volatile organic compounds (VOCs) compared to lower-cost alternatives that may only achieve 70% efficiency. Therefore, investing a bit more upfront can yield significant benefits in air quality control and operational efficiency.

Tips: When selecting activated carbon filters, always look for the specific adsorption capacity and test results from reliable sources. Additionally, bulk purchases can lead to cost savings, but it’s important to ensure that you’re not sacrificing quality for a lower price point. Always request sample sheets for testing before making a large order.

Furthermore, consider the application of the filters you need. For environments with heavy pollutants, a higher performance filter will save costs long-term by reducing the frequency of replacements. A detailed analysis from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends that businesses measure the cost of filter replacements against the benefits of improved air quality, which can lead to increased employee productivity and reduced health issues. Balancing your budget with desired outcomes will lead to a more informed purchasing decision.

When it comes to sourcing the best wholesale activated carbon filter sheets, quality and reliability should be at the forefront of your decision-making process. The global activated carbon market has been projected to grow at a CAGR of approximately 10% from 2021 to 2026, reaching an estimated value of $4 billion by 2026, according to industry reports. This growth indicates an increasing demand for high-quality activated carbon products across various applications, such as air and water purification, industrial processes, and even food and beverage production. When selecting suppliers, it's crucial to ensure that they adhere to industry standards for product quality and performance.

To find the most reliable wholesale suppliers, consider platforms that specialize in industrial-grade materials and have a proven track record in the activated carbon sector. Look for suppliers that provide certifications such as ISO 9001 or those that have undergone third-party testing to guarantee the effectiveness of their products. It’s also beneficial to explore trade shows and industry exhibitions, where you can interact directly with manufacturers and distributors. Networking in these settings can give you access to valuable insights into market trends and technological advancements, allowing you to make informed decisions tailored to your specific filtration needs.